The Problems we solve

PreOne is solving the global plastics waste problem by creating a circular economy where everyone benefits

Waste Collectors

Packaging Manufacturers

Big brands and retailers

PreOne For Waste Collectors

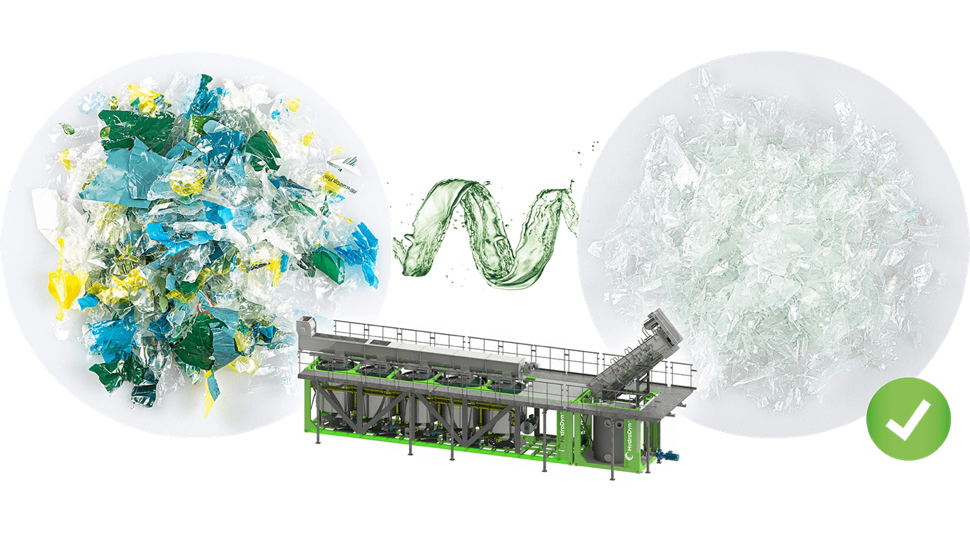

The HydroCleaner “Spokes” are decentralised facilities that pre-washes waste plastic, keeping the dirt in the dirty world of waste and converts waste into a valuable feedstock.

The role of the HydroCleaner

- Processes highly contaminated, unsorted waste plastics

- An “omnivore”, can process all plastic types

- Remove contamination to approximately 1% residual

- Segregate the dirty waste world from the purification hubs

- Densified and cleaned for optimum transportation

Benefits

- Leased to the waste collector, low barrier to entry

- Deployed to where the waste is controlled

- The waste collector is contracted to supply the feedstock

- Feedstock prices are set and adjusted to promote circularity

- Provide technology that allows many collectors to participate without the risk

The PreOne Business Model

Co-investment engages the right stakeholders for circularity and fairly shares value throughout the chain, whilst tracking the material responsibly to meet stewardship and legal compliance

- HydroCleaners Lease to collectors. Permits the rapid expansion of capacity and low barrier to entry for a range of feedstock partners across multiple locations. Flexible: can adapt quickly to a change or mix of feedstock suppliers.

- JV partners to bring continuous feedstock Feedstock partners are rewarded for higher offtake prices.

- Equity stake in the Purification Hub keeps feedstock and offtake partners equitably engaged. A centralized purification site is separated from the dirty world of waste.

- JV Partners provide offtake to their chosen converters, virgin resin manufacturers or distributors with remanufactured resins made to their specification.

Our Mission

Our mission is to revolutionize plastic waste into a renewable resource.

With a vision to ultimately create an infinitely sustainable planet, at PreOne, we transform polypropylene plastic into a versatile, replenishable resource through our unique purification process. Our ultra-pure recycled plastic can be recycled and reused multiple times, changing our relationship with plastic.

Featured In:

PreOne for Brand Owners

The Purification “Hubs” are centralised facilities that specialise in purifying polymers to food grade quality and generate a resin that is close to virgin quality.

The role of Purification

- Receives pre washed polymer feedstock from the collectors

- Sorts, purifies, de-inks, strips VOC’s, blends and pelletises remanufactured resin

- Produces customised specifications for every customer application

- Near virgin quality output

Benefits

- The Pure hub is operated by PreOne

- Value chain partners who have an influence over offtake are invited to share in the benefits of the joint Venture

- Complete transparency is provided to our JV partners

- Offtake is assured

The Benefits of PreOne

Food grade ready

for 2025 certification

- Stable pricing

- Profit participation

- Diversified global offtake network

- Technical competency to deliver customized product specifications

- Reliable quality and service

- Global manufacturing and supply chain network

- Environmentally sustainable solution, with lowest carbon impact